Purpose

The choice and tryout of the design of the hydraulic flow systems of industrial apparatuses in different industries (the chemical industry, the power industry, metallurgy, etc.) to increase the efficiency of the production processes in the working area of the apparatus.

Essence of the technology

Сombined use of computational methods and experimental modeling of gas-dynamic processes with model plants of different scale (including full-scale ones).

Advantages

The technology is implemented using inexpensive model equipment and shortens (or fully eliminates) the stage of flow system tryout with the use of pilot and industrial plants.

Operational testing

In the development of chemical apparatuses and space vehicle ground temperature control systems.

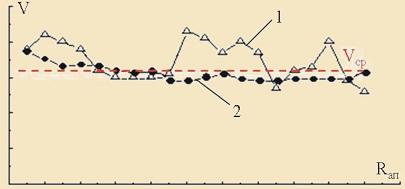

Development of the design of the gas distributor of an industrial ammonia conversion apparatus

The gas input is of the jet type. Inlet pipe diameter – 500 mm. Maximum diameter of the apparatus – 4,000 mm. Gas distributor diameter – 4,000 mm. Distance between the inlet and the gas distributor – 1,750 mm

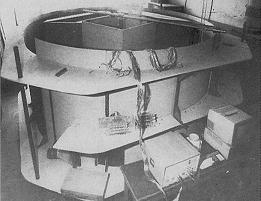

Development of the flow system of an industrial spouted-bed apparatus to coat granulated ammonium nitrate

The try-out of spouting processes using plants of different scale allows one to reveal scale effects that take place when going from model small-scale plants to full-scale industrial apparatuses

Development of the general and the local ground temperature control system of the spacecraft housing of the Zenit launch vehicle

The objective of the development – the choice of the design of temperature-controlling air input and distribution devices to provide the required heat removal from the spacecraft instruments at the minimum air speed during the prelaunch preparation on the launching site.

Services

Gas-dynamic analysis of the apparatus flows, recommendations on improvement of the original design, and its choice and experimental development with consideration for its manufacturability.

| Contact information: | |

| Institute of Technical Mechanics | of the NASU and SSAU |

| Ukraine 49005 Dnipro 15 Leshko-Popel St. | |

| Contact person: | V.I. Tymoshenko |

| Phone. | (056) 372 06 41 |

| E-mail: | vitymoshenko@nas.gov.ua office.itm@nas.gov.ua |

| Web: | http://www.itm.dp.ua |