Physical statement of problem. The following physical picture of processes is characteristic for technological devices of a high-speed gas flame spraying of coatings, thermo-abrasive processing and jet grinding. The particles together with hydrocarbonaceous combustible and oxidant move to the combustor of gas-dynamic passage, in which there is their acceleration, heating and, in a case necessities, melting. The additional acceleration of particles takes place in a free supersonic jet. The acceleration of carrier gas in a gas-dynamic passage is made at shape of passage or by using of additional gas feeders. Terminating processes happen in an shock layer generated at impact of a two-phase jet about handled surface or at collision of jets.

Mathematical Models. The two-phase flow in a gas-dynamic passage of the gas-dynamic device is described by quasi one-dimensional equations of gas dynamics which are taking into account friction and convective heat exchange of for a two-phase flow with the passage walls as well as friction and heat exchange between phases. The parameters of a two-phase flow at the feeders outlet are calculated using balance rations on known parameters at feeder inlet and ones supplied through its walls. Particle parameters at passage through gas inlet section are stable. The supersonic flow in a free supersonic jet is described by hyperbolic two-dimensional equations. Heat exchange and interphase friction are taking into account. The equation numerical integration is carried out with the use of marching lengthwise the jet axis.

Software product”Two_Phase”. The software product can be used for researches of thermogas-dynamic processes in the passages of gas-dynamic devices to most fully use chemical energy of a fuel for heating and acceleration of particles, as well as to select rational geometric parameters of passages. The software product provides a user with the information on its purpose, structure and capabilities. A brief description of physical and mathematical formulations of the problems solved is given. The software product provides means for formation and remembering of the problem input data to carry out current calculations. It ensures processing and storage of the calculation results. The software product works in the interactive dialogue mode with using the terms and determinations from the data domain of software product purpose. The practical work with the software product does not require from the user a special training in the area of programming and learning special operating instructions. The user’s work with the software product is reduced to the following sequence of operations: choice of a problem; specifications of the input data of the problem according to the submitted prototype of their defaults; choice of the way of results representation from the list of the proposed complexs of the kinds of problem processing; the problem start-up for calculation; solution results representation of the selected problem on the monitor screen in the form of numerical or graphic information depending on selected kinds of solution processing; the storage of the current calculation results in the result bank; comparison of the obtained results with the earlier obtained results of the selected problem under different input data of the problem.

The use of the software product “Two_Phase”, allows:

- to estimate discharge characteristics of the installation, gas-dynamic and thermo-physical characteristics of combustion products;

- to estimate the range of change in dynamic and power parameters of particles in the gas-dynamic device passage and in feeders;

- to calculate the field parameters of gas and particles in the gas-dynamic device passage and two-phase jet flowing out of the passage;

- to choose the geometric and regime parameters values of the gas-dynamic device for obtaining the maximum values of the particles power parameters;

- to calculate the composition of combustion products, their thermodynamic and thermophysical properties;

- to calculate the interphase interaction parameters;

- to determine the disperse phase thermal condition (temperature field, degree of melting) at its motion in the of gas-dynamic device passage.

Results Representation. User has an opportunity to present results of calculations as:tables of parameters at the gas-dynamic device passage outlet at various values of input parameters of the problem; diagrams of gas-dynamic parameters distributions along the gas-dynamic device passage axis; diagrams of parametric dependencies of flow parameters at the gas-dynamic device passage outlet on input parameters of the problem;isoline fields of flow parameters in the gas-dynamic device passage.

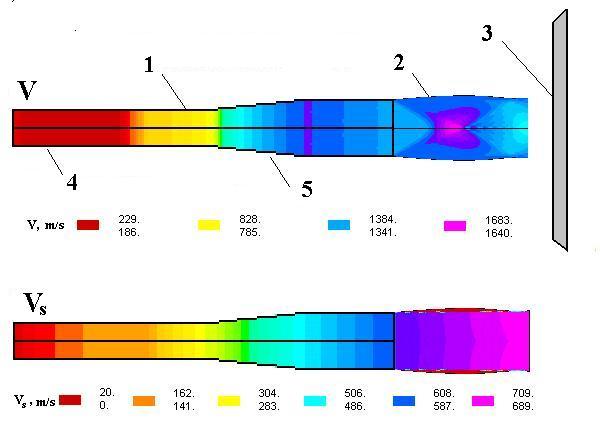

As an example of usage of the “Two_Phase” software product in figures are shown the schematic diagram of a gas-dynamic passage of a burning installation for a gas-flame spraying with additional gas feeders and relevant isolines of gas and disperse phase speeds.