In long-term service in orbit, the working surfaces of optical systems and windows are contaminated with dust particles from the near-vehicle environment and the products of station life activity, vernier and stabilization engine exhaust, and spacecraft surface material destruction and gassing. Because of this, transparent optical elements must be cleaned. The problem of the development of methods and means for transparency recovery aboard spacecraft is rather complex yet highly topical for providing a long active life of spacecraft.

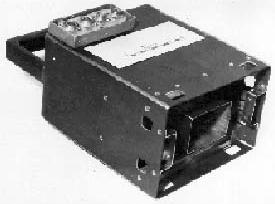

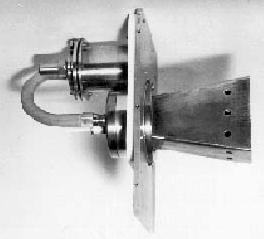

At the Institute of Technical Mechanics of the National Academy of Sciences of Ukraine and the National Space Agency of Ukraine, a technology and a device have been developed for plasmochemical surface cleaning with an oxygen plasma jet. The device is a self-contained compact unit, which can be fixed on the spacecraft surface or be used by an astronaut in his extra-vehicular excursion. The unit includes a plasma jet source, a gas feed system, and a control system. To produce oxygen, a solid body is used, thus providing a small size, ease of use, safety, and high reliability of the working substance storage system in long-term service in orbit.

The plasma source is a closed electron drift accelerator with an extended acceleration zone, wherein a flared shield emitting photo- and secondary electrons is used for flow formation, ion focusing, and volume charge neutralization. The secondary emission process is due to exposure to the plasma ultraviolet radiation and the ion flow. This greatly simplifies both the accelerator design and the system as a whole. The working solid is stored in a special capsule. To deliver the oxygen produced by thermal decomposition of the working solid and control its flow rate, a special system is used. The accelerator discharge current feedback circuit controls the flow rate by varying the heater power.

In comparison with other methods, this method of plasmochemical cleaning with oxygen plasma jets of ion energy up to 600 eV allows one to treat the largest area and is the most economic, friendly to the surface under treatment, efficient, simple, and reliable.