Department of power plant thermogas dynamics

Head of department – D.Sc., Professor Hennadii O. Strelnykov

Key specifications

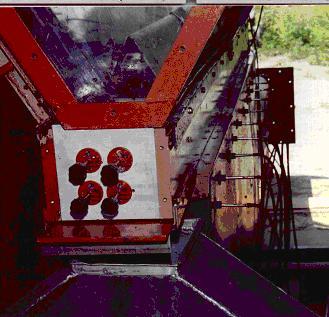

| Grate dimensions, mm | 1950×500×40 |

| Number of grate nozzles | 148 |

| Nozzle diameter, mm | 10 |

| Nozzle spacing, mm | 25 |

| Grate area, m2 | 0,301 |

| Charging material mass, kg | 10 – 90 |

| Air flow rate through the grate , m3/h | 2·105 |

Description

The bench is intended for comprehensive tests of gas-distribution grates used for the formation of various types of a fluidized bed of a coal imitator and for the gas-dynamic transportation and drying of loose materials.

The bench allows one to visually observe the spouting process and to use various polydisperse mixtures for fluidization. The bench is of the delivery-under-pressure type. Compressed air is delivered by two fans placed in tandem.

The vane-slot bottom grate makes possible gas-dynamic transportation and various types of a fluidized bed. Controlling the tilt of the grate vanes puts the material in motion over the grate and prevents slagging and heaping. The streamlined tiltable vanes installed in the longitudinal slots of the grate make it possible to control the charging process, to distribute the solid fuel uniformly along the length of the grate, and to remove the solid combustion residue. The grate makes possible any type of a fluidized bed: boiling, bubbling, and spouted, thus making the firing of a fluidized-bed boiler furnace much easier.

Capabilities

- Study of gas-dynamic transportation;

- Tryout of loose material drying regimes;

- Putting the material in circulatory motion;

- Fluidized flow characterization;

- Variable configuration of the bottom grate.

Advantages

- Controlled vane tilt;

- Visual observation of the process;

- Process parameter measurement;

- Low drag of the grate.

Use

The capabilities of the bench are used for experimental studies in the fuel-energy complex, agriculture, the food industry, and other sectors of the national economy.

| OFFICE ADDRESS: | Institute of Technical Mechanics, 15 Leshko-Popelya St., Dnipro, Ukraine, 49005 |

| PHONE NUMBER: | +38-056-372-06-45 |

| E-MAIL: | office.itm@nas.gov.ua |