Department of power plant thermogas dynamics

Head of department – D.Sc., Professor Hennadii O. Strelnykov

| Key specifications | |

| ГPipeline dimensions D×L, m | 0,52×8…16 |

| Work chamber dimensions, m | 1×1×1,2 |

| Fan total pressure, kPa | 1600 |

| Ts 14-46-8K centrifugal fan delivery, m3/h | 28000 |

| Maximum dust concentration per kilogram of air, kg | 1,5 |

| Maximum flow speed at the pipeline exit, m/s | 38 |

| Cyclone models: | |

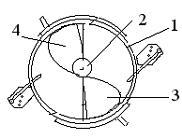

| Outer cylinder, m | R1 = 0,68 |

| Inner cylinder, m | R2 = 0,2 |

| Area, m2 | 0,025 — 0,12 |

| Swirl angle | α1 = 50° , α2 = 17 — 22° |

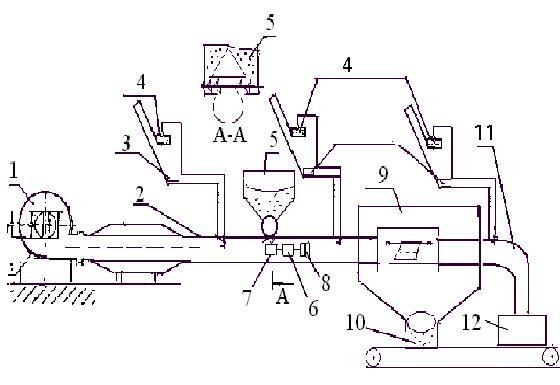

3, 4 — measuring elements, 5 — ash bin,

6 — motor, 7 — worm reducer,

8 — revolution meter, 9 — cyclone model chambers,

10 — solid-particle collector, 11 — air duct exhaust,

12 — two-phase flow cleaning system

cylinders

3, 4 —screw blades,

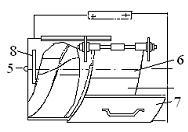

6 — plate to control the

window flow area,

7, 8 — gate valves.

Description

The bench serves to study and try out processes of interaction of low-pressure single- and two-phase flows with aerofoils, grates, and other objects. Low-pressure air is delivered by a controlled-delivery fan into a pipeline connected to the fan by an elastic spacer. The exit of the pipeline is connected to a work chamber mounted on a rail-guided cart.

Capabilities

- Study of the filtration of a two-phase flow;

- Air filter tryout;

- Aerodynamic drag, force, and moment determination;

- Dust fractional composition determination;

- Testing of screw-type cyclone models.

Advantages

- The self-contained compressor permits long-term rests.

- Various systems for process parameter measurement.

Use

The bench is intended to test screw-type cyclone models.

Using the bench, recommendations are worked out on the choice of cyclone models and a two-phase flow cleaning system.

A cyclone for a heat and power plant boiler has been tried out on the bench.

| OFFICE ADDRESS: | Institute of Technical Mechanics , 15 Leshko-Popelya St., Dnipro 49005, Ukraine |

| PHONE NUMBER: | +38-056-372-06-45 |

| E-MAIL: | office.itm@nas.gov.ua |