Department of power plant thermogas dynamics

Head of department – D.Sc., Professor Hennadii O. Strelnykov

| Key specifications | |

| Feed pipe inner diameter, m | 0,125 |

| Pipe length, m | 1,500 |

| Optimum linear gas speed at the pipe inlet, m/s | 8 ± 1 |

| Optimum specific consumption of cleaning water, kg/m3 | 0,2 — 0,3 |

| Efficiency of liquid flow cleaning, % | 99,6 — 99,8 |

| Hydraulic resistance, millimeters of water | 55 |

| Gas temperature at the emulsifier pipe inlet,°С | 140 — 150 |

| Gas temperature at the pipe outlet,°С | 52 — 58 |

| Swirler type | Plate type |

| Capacity, m3/h | 350 |

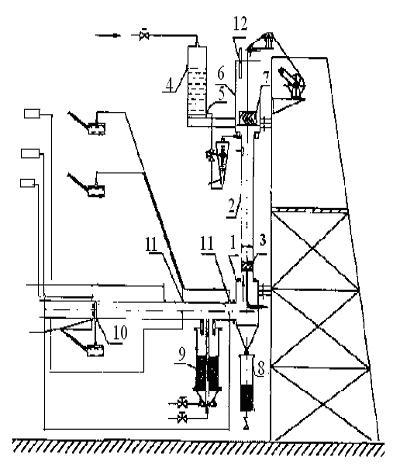

2 — emulsifier pipe,

3 — swirler,

4 — discharge nipple,

5 — nipple for water feed into the emulsifier pipe,

6, 7 — drop catcher chamber and drop catcher,

8 — mud collector,

9 — dosing unit,

10, 11 — total and static pressure probes,

12 — thermometer.

Description

The bench is intended for the study of dust and gas cleaning of two-phase flows and for tests of various models of filter elements of dust and ash catchers and models of cyclones, scrubbers, etc. Tests are conducted using a transparent model of an emulsifier filter element and its variations, which makes it possible to visually observe the process of interaction between the gas-air flow and the water, splash entrainment, and mud rundown and to determine the quantitative parameters and characteristics of this interaction.

Capabilities

- Study of emulsifier gas path aerodynamics.

- Visual observation of the process.

- Process characterization.

- Testing of various models of dust and ash catchers, cyclones, and scrubbers.

- Tryout of emulsifier filter elements.

Advantages

- Formation of a directed air flow.

- Introduction of dust into a clean air flow.

- Feed of water interacting with the swirled ash-air flow.

- Heating of the ash-air flow up to 1500 – 1600С.

- Flow parameter measurement.

- Water and collected ash (dust) mass measurement.

Use

Study and tryout of scrubbing and dry cleaning of combustion gases. Tryout of cleaners for heat and power plants and industrial enterprises.

The study of cleaning by emulsification has made possible an ash catcher with a separation efficiency up to 95% at a hydraulic resistance of no more than 1.8 kPa.

| OFFICE ADDRESS: | Institute of Technical Mechanics , 15 Leshko-Popelya St., Dnipro, Ukraine 49005 |

| PHONE NUMBER: | +38-056-372-06-45 |

| E-MAIL: | office.itm@nas.gov.ua |