Purpose

Extended service life of trucks and improved dynamic performance of freight cars.

Essence of the technology

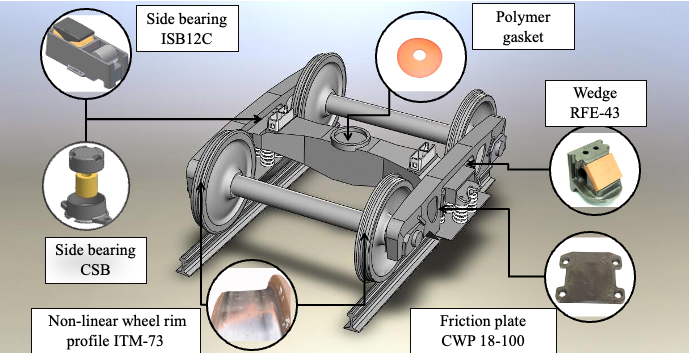

Replacing standard friction assemblies with new, more durable ones and introducing new devices into the construction to improve dynamic car performance.

Advantages

Truck retrofit is possible both for cars in service and for new cars. On retrofit, the car cost increases by 3 to 4 percent only while the service life of the major-wear parts shows a several-fold increase (a ten-fold increase for some parts).

Testing and implementation

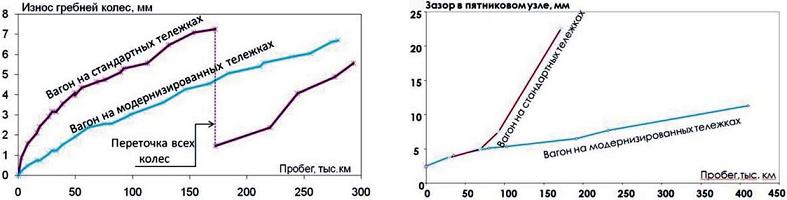

Operational and dynamic tests of cars together with their inservice inspection have confirmed and in some cases surpassed the predicted efficiency of the proposed retrofit.

A project of complex retrofit of freight-car trucks, C03.04, has been developed and introduced. The retrofit uses three elements of the A.Stucki Co. (USA) and the ITM-73 wear-resistant wheel profile (Ukraine). The retrofit is in progress at all the Ukrainian car-repair plants and ten Ukrainian car shops. A system of repair and maintenance of retrofitted cars has been set up. Patents have been issued for: the ITM-73 wear-resistant wheel profile, which halves wheel flange wear; resilient roller side bearings, which offer a higher critical car speed, and friction wedges, which extend the service life of the wedge damping system by a factor of more than ten.

| Major characteristic | Retrofit by Project C03.04 (Ukraine) | Retrofit by Project М1698 (Russia) | UVZ truck(Russia) |

| Life, km x 1000: wheel flange (machining life), wedge damping system, center plate arrangement | 300-400 1000-1200 700 | 100-150 160-210 160-210 | 100-150 160 N/A |

| Critical speed of empty cars with medium–worn wheels, km/h | 120 | 60-80 | 110-120 |

| Repairability | No need for power–intensive repair work | Truck part reclamation during shop repairs | N/A |

| Cost, USD | 2000-2500 | 450-550 | N/A |

| Pay–back period, years | 1,8-2,3 | no less than 5 | N/A |

Major publications

1. Ushkalov V.F. On possible improvement of the dynamic performance of a freight car and reduction of wheelrail wear (in Russian) / V.F. Ushkalov, T.F. Mokrii, I.A. Mashchenko, L.A. Galchenko // Tekhnicheskaya Mekhanika. 2000. No 1. Pp. 83-89.

2. Ushkalov V.F. On evaluation of the efficiency of wheels with different tread profiles in railway cars (in Russian) / V.F. Ushkalov, T.F. Mokrii, I.A. Mashchenko, I.Yu. Malysheva // Tekhnicheskaya Mekhanika. 2002. No 2. Pp. 121-127.

3.Ushkalov V.F. Freight-car running gear retrofit (in Russian) / V.F. Ushkalov, T.F. Mokrii, M.M. Zhechev, I.A. Serebrianyi, I.Yu. Malysheva // Zaliznychnyi Transport Ukrainy. 2003. No 5. Pp. 33-36.

4. Hansen Gregg W.M. Complex retrofit of 18-100 trucks to reduce wheel wear and improve the ride performance of freight cars (in Russian) / W.M. Gregg Hansen, A.D. Lashko, V.F. Ushkalov, T.F. Mokrii, I.Yu. Malysheva, I.A. Mashchenko // Visnyk Dnipropetrovskogo Natsionalnogo Universytetu Zaliznychnogo Transportu im. Ak. V. Lazariana. 2004. Issue 5. Pp. 215-219.

5. Ushkalov V.F. Complex retrofit of freight-car running gear (in Russian) / V.F. Ushkalov, T.F. Mokrii, I.Yu. Malysheva, I.A. Mashchenko, S.S. Pasichnik // Vagonnyi Park. 2007. No 2. Pp. 18 – 22.

Patent protection

1. Ushkalov V.F., Mokrii T.F., Mashchenko I.A. Flange fillet (in Russian). Russian Federation Utility Certificate No 22100 10.03.2002.

2. Ushkalov F.F., Mokrii T.F., Mashchenko I.A. Railway wheel tread profile (in Russian). Russian Federation Utility Certificate No 26208 20.11.2002.

3. Ushkalov V.F. (UA), Gatnarek Bruce (US), Rhen Dennis (US). Resilient roller side bearing (in Russian). Russian Federation Utility Certificate No 29020 27.04.2003.

4. Ushkalov V.F. (UA), Gatnarek Bruce (US), Right James (US). Friction wedge (in Russian). Russian Federation Utility Certificate No 29276 10.05.2003.

5. Ushkalov V.F., Mokrii T.F., Mashchenko I.O. Flange fillet (in Ukrainian).Ukrainian Patent for Utility Model No 1181 15.03.2002. Bulletin No 3.

6. Ushkalov F.F., Mokrii T.F., Mashchenko I.A. Railway wheel tread profile (in Ukrainian). Ukrainian Patent for Utility Model No 1182 15.03.2002. Bulletin No 3.

7. Ushkalov V.F. (UA), Gatnarek Bruce (US), Right James (US). Friction wedge (in Ukrainian).Ukrainian Patent for Utility Model No 1803 15.05.2003. Bulletin No 5.

8. Ushkalov V.F. (UA), Gatnarek Bruce (US), Rhen Dennis (US). Resilient roller side bearing for freight-car trucks (in Ukrainian). Ukrainian Patent for Utility Model No 1802 15.05.2003. Bulletin No 5.

9. Ushkalov V.F. (UA), Gatnarek Bruce (US), Rhen Dennis (US). Resilient roller side bearing (in Ukrainian). Ukrainian Patent for Utility Model No 1804 15.05.2003. Bulletin No 5.9.

| Contact information: | |

| Institute of Technical Mechanics of the NASU and SSAU | |

| Ukraine 49005 Dnipro 15 Leshko-Popel St. | |

| Contact person: | T. F. Mokriy |

| Phone: | +38 (056) 372 06 40 |

| E-mail: | mokriyt@gmail.com office.itm@nas.gov.ua |

| Web: | http://www.itm.dp.ua |