Department of hydromechanical and vibration protection systems dynamics

Head of department – Academician of the National Academy of Sciences of Ukraine, D.Sc., Professor Oleg V. Pylypenko

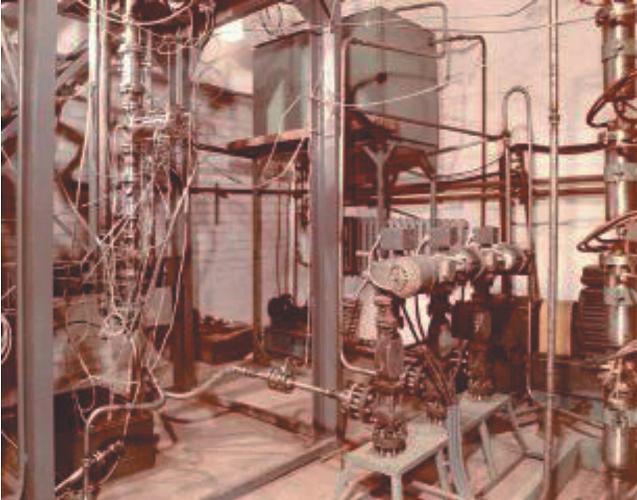

The dynamic facilities for simulation the damper work conditions, including a cryogenic damper, are created. Theoretical and experimental studies of the dynamics of nonequilibrium thermodynamic processes of evaporation and vapour condensation in two-phase vapour and liquid flows were executed. Obtained results have allowed to make a conclusion about an appropriate use of the dynamic properties of two-phase vapour medium for the development and creation of radically new highly-efficient vibroprotection equipment for various technical objects and systems.

The basis for a theory and the design of radically new highly-efficient thermodynamic and pneumatic vibroprotection systems with quasi-zero stiffness on a working section of the static characteristic is provided. Offered vibroprotection systems allow providing a very low natural frequency and do not require any hydraulic shock-absorber for dissipation of vibrational energy. Obtained results are used to develop a radically new pneumatic car suspension with separated damping high-frequency and low-frequency vibrations, vibroprotection module for car driver’s seat, vibroprotection systems for hand-operated pneumatic percussive machines, etc.

The pneumatic vibroprotection module for driver’s seats (tractors, trolley-bus, trucks, etc.) is designed. This allowed the driver’s reaction to vibrations to be decreased ~ 3 times in comparison with the best world counterparts.

From the results of the dynamic tests of the YuMZ-T2 trolley-bus and YuMZ-6aKL tractor driver’s seats with the pneumatic vibration-protection module developed at the Institute of Technical Mechanics of NASU & NSAU, a maximal frequency of the seats vibrations does not exceed ~ 1.2 Hz, and a maximal amplification factor at a resonance vibration frequency does not exceed ~ 1.2, resulting in lower permissible standards.

The obtained results of the dynamic and life tests allow the ITM’s vibration-protection module to be recommended for fitting to the driver’s seat suspension for varied transportation facilities.

The design is proposed, and the prototypes of the new pneumatic car suspension are fabricated. After determining the static and dynamic characteristics the suspension is fitted to the production car, and road tests are carried out. The decrease in a natural vibration frequency of the sprung mass of the car with the new suspension can pay a decrease in human reaction to vibrations 3 times for the asphalt-concrete road and 6 times for the cobble-asphalt road.

Performance of the new pneumatic suspension meets the requirements for smoothness and dynamic stability of the first-class car. The cost of the suspension does not exceed the cost of the standard suspension fabricated on the basis of metallic flexible members and hydraulic shock absorbers.