Purpose

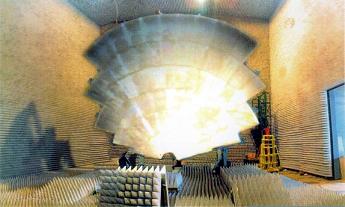

Manufacturing of thin-walled an-tenna/waveguide devices and solar concentrating systems, creation of optimum antenna/waveguide structures and minimum-weight solar concentrating systems.

Essence of the technology

Multipurpose use of electroforming (current-induced crys-tallization of a metal from a supersaturated near-cathode electrolyte layer). The surface of the electrodeposit is a precise replica of that of the matrix cathode, and a large number of identical products with a high-quality reflective surface can be made.

Advantages

High manufacturing accuracy, small mass, controlled uniformity of the material distribution in the electrodeposit (structural homogeneity of the material). Possibility of making complex-structure antenna/waveguide deices and solar concentrating systems, which cannot be made by other technologies. Assurance of the required strength, stiffness and longevity. The technologies fall into wasteless and energy-saving ones.

Operational testing

In the development of space antenna/waveguide devices, radio astronomy devices and solar plants.

Parabolic mirror antennas and solar concentrators

| Diameter 0.5 – 1.6 m, variable thickness 0.2 – 0.5 mm |

Waveguides of different types

Cone and pyramid antennas

Small parabolic concentrators and the apparatus to make them

Services

Transfer of documentation for methods of manufacturing of antenna/waveguide devices and solar concentrating systems including (a) flowcharts specifying the operation sequence and operating conditions (temperature, electrolyte composition, etc.); (b) design and production documentation for products and equipment. Development of processes for the manufacturing of new complex products (seamless pipes, diaphragms, bellows, floats for oil storage metering systems).

| Contact information: | |

| Institute of Technical Mechanics of the NASU and SSAU | |

| Ukraine 49005 Dnipro 15 Leshko-Popel St | |

| Contact person: | V. P. Poshivalov |

| Phone: | +(380)-56-376-45-86 |

| E-mail: | poshivalov.v.p@nas.gov.ua office.itm@nas.gov.ua |

| Web: | http://www.itm.dp.ua |