Department of aerogas dynamics and technical systems dynamics

Head of Department – Corresponding Member of the National Academy of Sciences of Ukraine, D.Sc., Professor V. I. Tymoshenko

Description

The bench is an assemblage of one or more compressed air sources, a full-scale model of the flow system of the process apparatus under study with replaceable elements, and instrumentation for gas-dynamic parameter measurement, thus allowing one to model and effectively try out the flow system and operating conditions of the apparatus.

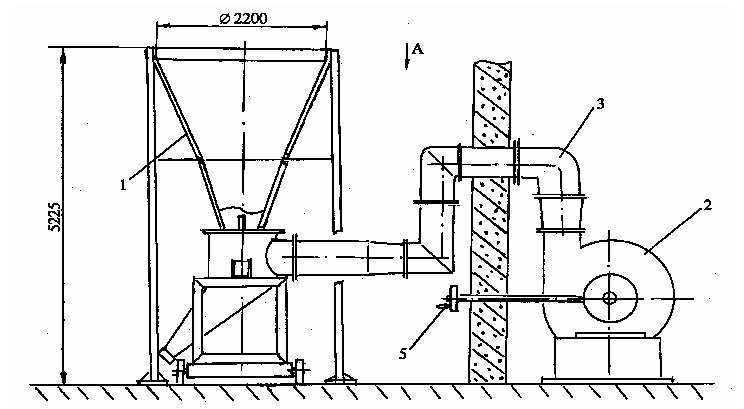

1. Bench layout in the tryout of the inlet of a spouted-bed apparatus

Assembly configuration of the bench

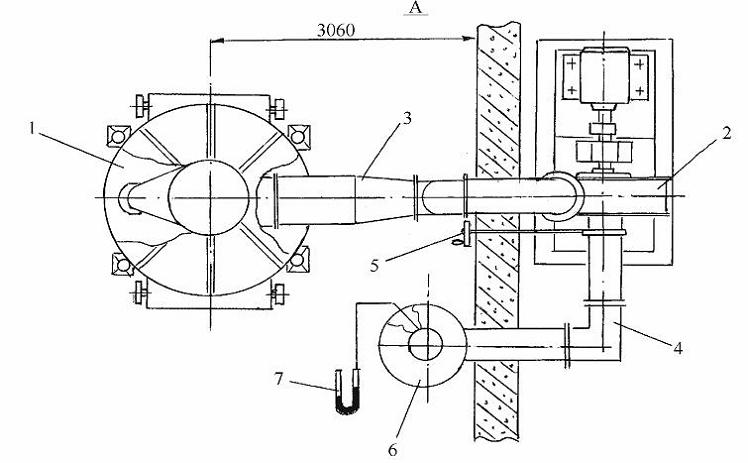

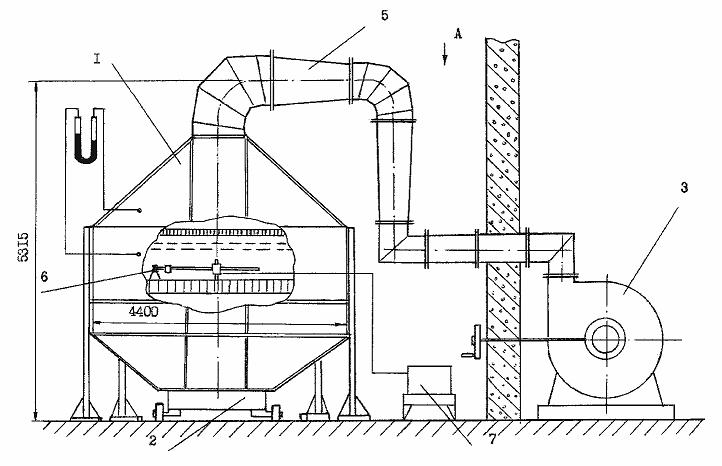

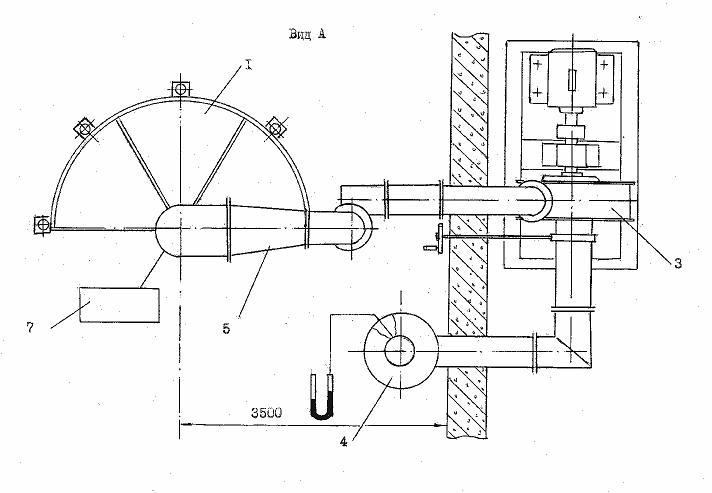

2. Bench layout in the tryout of the design parameters of a ground thermostating system for the spacecraft compartment of the Zenit-2 launch vehicle

Assembly configuration of the bench

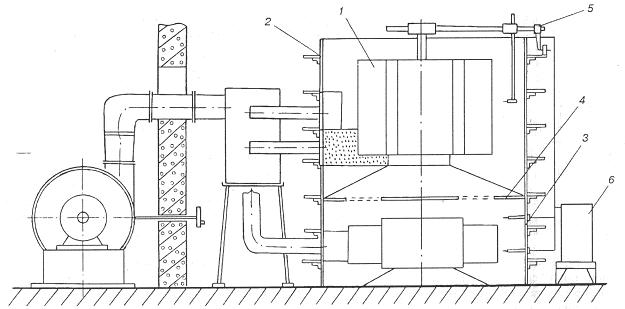

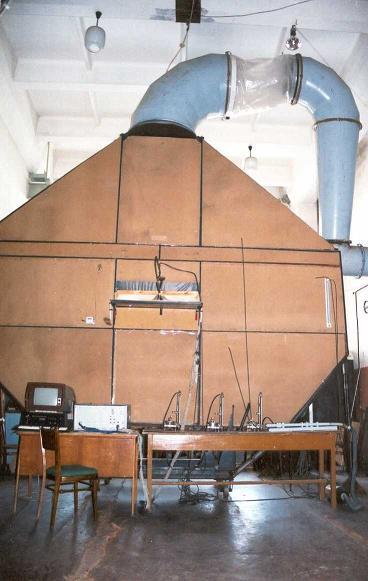

3. Bench layout in the choice and tryout of a gas distributor for an ammonia conversion apparatus

Assembly configuration of the bench

Key specifications

| Air sources | High-pressure fans,, gear and piston compressors |

| Power consumption | No more than 50 kW |

| Maximum overall dimensions of model apparatuses | depth up to 6,000 mm; dimensions in plan 5,000х5,000 mm ² |

| Air flow rate | Up to 20,000 m³/h |

| Flow speed | Up to 60 m/s (with fans) |

| Model materials пWood chipboards, | fiber boards, foamed plastic, sheet metal, steel sections |

| Instrumentation | heat-loss anemometers , microvane anemometers, liquid, semiconductor, pointer-type pressure-and-vacuum gages, proprietary total and static pressure heads, Sapfir 22DD differential pressure pickups, thermocouples, PC with data processing software |

Capabilities

The bench allows one to try out flow systems and operating conditions for process equipment using full-scale models and separate industrial units.

Advantages

Elimination of scale effects when going from small-scale model apparatuses to full-scale industrial ones.

Use

Choice and tryout of the design parameters and operating conditions of process apparatuses and a system of ground thermostating of launch vehicle compartments.

| OFFICE ADDRESS : | Institute of Technical Mechanics , 15 Leshko-Popelya St., Dnipro 49005, Ukraine |

| PHONE NUMBER: | +38-056-372-06-41 |

| E-MAIL: | vitymoshenko@nas.gov.ua |